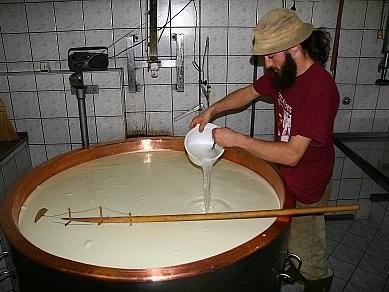

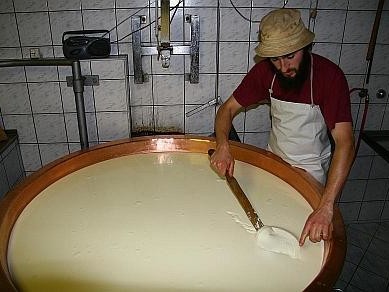

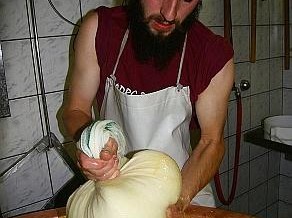

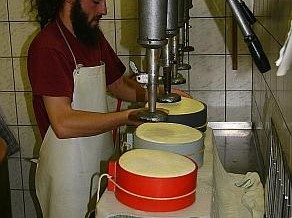

DAIRY FARMING

![]()

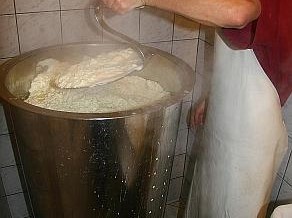

Our cheese is famous mainly for its long history and traditional processing. The climate in the Upper Posočje valley provides perfect conditions for the quality of milk required for our cheese. It can be classified among hard full fat cheeses. The basis of its production is our raw cow milk.

The first documents about cheese Tolminc can be traced back to the 13th century, when it was listed as a means of paying land taxes to feudal lords. The name ‘Tolmin cheese’ first appeared in 1756 on a price list of cheeses in Videm, Italy.

Nowadays cheese in the Tolmin region is produced during the summer season in the mountain dairy farms as well as some of the village ones. Dairy farming is also an extra sideline for the three eco farms in Čadrg.

Side products of cheese production

We also invite you to take a look at the brochure: “Whey, the milk secret”.

The author of the photos about dairy farming is Dario Cortese.